Port operations play a crucial role in the logistics industry. Without efficient workflows, organized layouts, and safe operations, ports can create bottlenecks in the supply chain, slowing down the transport of goods and affecting industries across the world. That’s why powerful and dependable technology solutions are necessary for meeting port demands successfully.

With automated equipment on the rise across countless industries, more ports are turning to automation to power various workflows. Among the many technologies making automation possible is lidar, or light detection and ranging. Learn more about the role of lidar technology in port automation and how these innovative solutions are revolutionizing operations.

The Benefits of Lidar in Outdoor Applications

To understand the full potential of lidar solutions in port applications, you need to know how lidar works and why it’s superior to other sensing and navigation technologies. Lidar systems use light beams to detect objects, people, and terrain. The system emits light beams that bounce off nearby surfaces and return to the lidar sensor, which then translates the distance those light beams traveled into data points that build an accurate view of the surrounding area.

The use of light beams makes lidar an ideal solution for outdoor applications. Lidar systems function at any time of day despite lighting and weather conditions. This allows port equipment to continue to operate at night and in rainy, foggy, or windy conditions. Furthermore, lidar technology undergoes significant weather testing to ensure it can withstand temperature fluctuations, moisture, and other outdoor conditions. This is a crucial part of port operations that must continue working no matter the season, weather, or time of day.

Workflow Efficiency

One of the biggest benefits of lidar technology in port automation is its efficiency. Automation powers stronger, smoother, and faster operations. Without the need for manual input, vehicles and other heavy machinery can operate safely on their own. This reduces downtime for breaks, minimizes human error, and frees employees to focus on other tasks.

Lidar technology enables greater navigation so that automated solutions can move more accurately through their environments. Cranes can locate and handle containers with more precision. Automated vehicles use more reliable navigation to detect objects and avoid obstacles in their paths. Lidar improves all the different moving parts of your port to keep things running as seamlessly as possible.

Port Safety

Safety is another key advantage of lidar-powered port automation. Features like enhanced perception and obstacle detection help prevent accidents that would put employees, products, and equipment at risk. Moreover, automated equipment solutions remove the human element of various jobs. This pulls employees away from hazardous workspaces while also eliminating mistakes that stem from human error. With fewer equipment malfunctions, traffic accidents, and other problems associated with manual operations, ports can enjoy smoother, safer, and more productive workflows.

Key Applications of Lidar in Port Automation

With the ability to operate safely and reliably in all kinds of conditions, lidar presents several opportunities for port technology. From automated vehicles to enhanced security, here are a few of the most common port automation solutions that benefit from lidar.

Powering Port Cranes

Ports rely on cranes to move the thousands of shipping containers that come in and out of their facilities every day. The intense use of heavy machinery—especially around other vehicles and employees—creates a lot of safety risks. Lidar-powered automation improves accuracy and efficiency, allowing cranes to operate reliably without human intervention.

Lidar sensors in ship-to-shore cranes make loading and unloading ships faster than ever before. This reduces the amount of time ships need to spend at the port, which streamlines transportation and creates a more efficient supply chain. Automatic stacking cranes also use lidar to better perceive their environments and handle containers more effectively. This minimizes mistakes like collisions or misaligned containers to create a smoother, more reliable port organization system with lower rates of product or equipment damage.

Improving Port Vehicles

Among the many moving parts of a port are automated vehicles. Automated guided vehicles, internal terminal vehicles, and other mobile solutions must be able to navigate the area safely and efficiently. Lidar-powered navigation gives these vehicles a more comprehensive view of their surroundings. This enhances obstacle detection, improves reaction times, and makes it easier for vehicles to navigate unexpected hazards—such as clutter, puddles, and roadblocks—in their environment.

When automated vehicles can move through the port without interference, you can streamline traffic, minimize accidents, and enhance the movement and handling of goods and containers. This creates a seamless workflow that allows all the different aspects of your port to work in tandem with minimal disruptions.

Enhancing Port Security

Lidar is also useful in yard monitoring and other security operations. Because lidar applications deliver a detailed, real-time, 3D perception of an area, they can help security teams monitor port equipment and containers. Moreover, the ability to operate with no light or in inclement weather makes lidar a useful tool for overnight outdoor security.

Common examples of lidar-powered port security include fixed sensors and digital boundary monitors. However, this form of port automation isn’t limited to stationary solutions. Innovations like autonomous security cruisers can move throughout the port and help monitor the area alongside manual security solutions.

Versatile Solutions for Diverse Port Needs

Lidar isn’t a one-size-fits-all solution. There are several different features and options available, making it a versatile solution that can fit the diverse needs of different port automation applications, such as stationary equipment, autonomous vehicles, security systems, and more. For example, a short-range lidar system might be effective for a stationary crane that works in one fixed area. However, an autonomous vehicle that moves throughout the entire port might benefit from long-range lidar that allows for greater perception and longer reaction times when it comes across obstacles or hazards in its path.

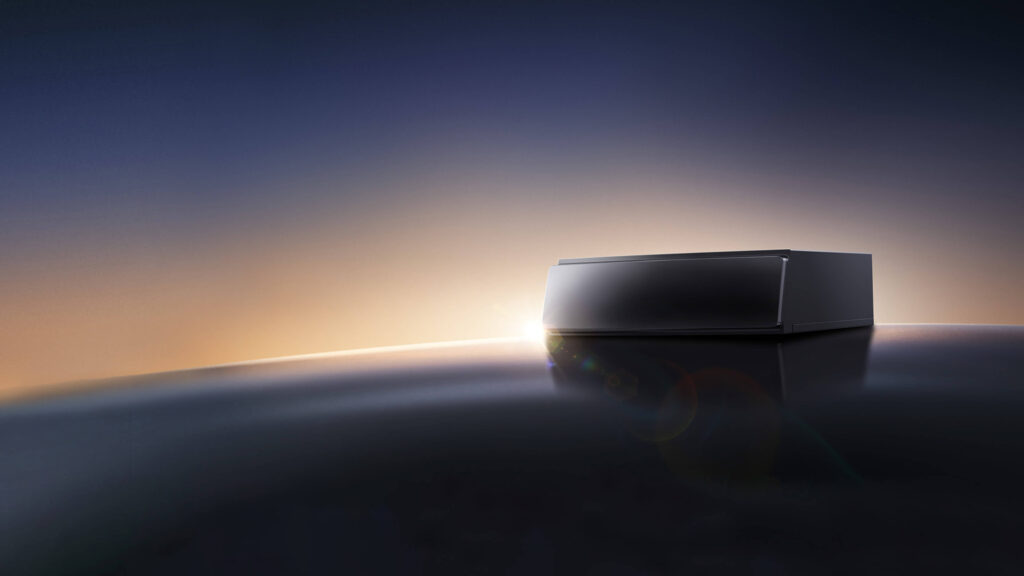

At Hesai Technology, we’re dedicated to creating advanced lidar sensors for autonomous industrial applications. With cutting-edge technology and design, comprehensive testing, and a passion for automation and all the opportunities it presents, we deliver versatile solutions to enhance a wide range of industries and businesses. Explore the vast potential of lidar systems in port automation solutions when you work with the Hesai team.