Industrial operations—including manufacturing, warehousing, logistics, and more—rely on efficient and responsible material handling. From a small forklift moving single product cases to a powerful tow tractor transporting multiple pallet loads, automated guided vehicles (AGVs) help move products and materials with better accuracy, safety, and productivity.

AGVs are not a new solution. In faction, they’ve been around since the 1950s. Today’s AGVs look a lot different than their predecessors, and the potential they bring to industrial facilities is limitless. Explore the advantages of modern AGV solutions and catch a glimpse of what the future has in store with this guide on everything you should know about the future of AGVs.

The Advantages of AGVs

Understanding how AGVs currently support warehouses, ports, and other operations makes it easier to see the vast potential of this technology. AGVs help streamline workflows with smoother and more efficient material handling. Relying on automated vehicles to move goods throughout your facility brings greater mobility and flexibility to your business. Autonomous forklifts, trucks, and other warehouse vehicles can move independently without employee interference. This frees up your team to focus on other jobs while moving materials, products, and pallets safely through your face ility.

Below are just a few of the key advantages that AGVs currently offer industrial operations.

Improved Worker Safety

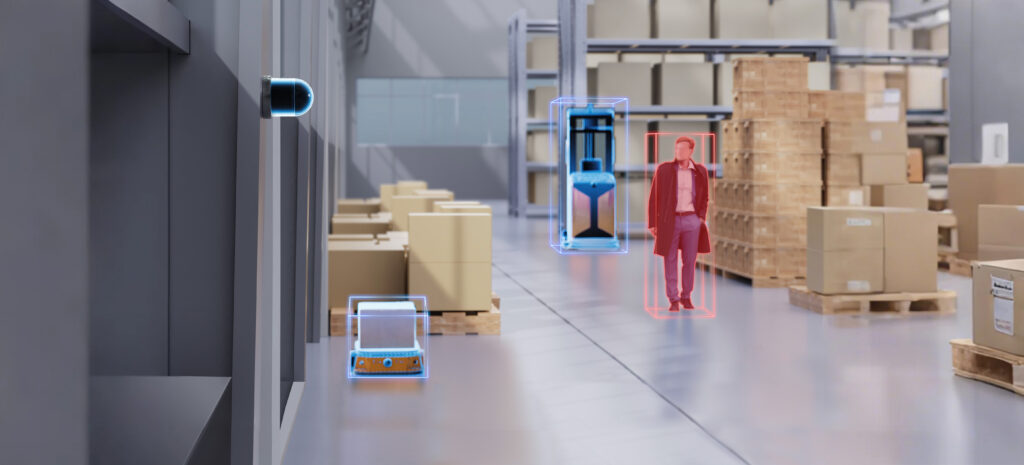

One of the greatest advantages of AGVs is the enhanced safety they can bring to industrial operations. As with any autonomous driving application, AGVs move smoothly and efficiently along their routes. This helps minimize traffic jams and collisions within your facility. Other safety features, such as obstacle detection and automatic emergency braking, also serve to minimize accidents and keep workers, vehicles, products, and other aspects of your operation safe.

Moreover, AGVs are designed to consistently follow best practices. This means that vehicles always carry balanced loads while driving at safe speeds along clear, optimized paths throughout the facility. These safeguards ensure that AGVs are a continuously valuable and dependable part of your workflow.

Smoother Material Handling

In addition to workers’ safety, AGVs help protect your products and materials. Autonomous vehicles are often smoother and gentler than manually driven vehicles. Where manual drivers might brake suddenly or turn sharply, AGVs maintain a consistent and safe pace throughout their routes. This helps keep products and materials secure as they move throughout your facility. With fewer trips, spills, and other accidents, you can minimize product damage, save money, and move goods through your workflow faster than ever before.

Fewer Human Errors

AGVs also increase accuracy and precision. For example, an employee in a warehouse might pull products from the wrong area or make a wrong turn when moving goods. Even small inaccuracies like these can slow down your workflow and lead to disruptions, missing materials, and other complications.

Because AGVs rely on computer programming and other sophisticated technology, they don’t make these kinds of mistakes. Improving accuracy in your facility means increasing productivity; goods move faster and more reliably, allowing the other stages of your workflow to continue operating efficiently.

The Use of Laser-Guided Vehicles

There are many different types of AGVs, but more and more businesses are relying on laser-guided vehicles utilizing lidar sensors to navigate and perceive their surroundings. Lidar technology brings a new level of accuracy and dependability to automated guided vehicles. For example, a lidar sensor can gather hundreds and thousands of data points per second to create a more precise perception of the surrounding area. With a higher level of detail and real-time visibility, lidar systems deliver enhanced obstacle detection to AGV applications, making them safer than ever.

As lidar and other technologies evolve, AGVs become even more valuable. The future of AGVs includes the potential for a wider range of automated tasks, smoother communication within technology networks, and a higher level of automation across industrial workflows.

An Entry Point for Automation

Automation is becoming increasingly common across a broad range of industries, but some businesses are still reluctant to adopt new technologies or don’t know how to begin implementing automation. AGVs are a great starting point for introducing automated technologies to your facility. They’re incredibly versatile and flexible, allowing you to customize your setup and use them to fulfill a specific need. You can also implement AGVs slowly. By purchasing one vehicle at a time, you can make small steps toward automating your workflow while also leaving room to grow in the future.

The Potential for 24/7 Operations

Unlike manual operators, AGVs don’t need breaks or time off. AGVs can continue working around the clock. As this technology becomes more commonplace across a more significant number of industries, it can significantly influence the way businesses view their workflows. This can lead to major operational changes regarding how businesses schedule workers or manage supply chains. AGVs enable 24/7 operation for warehouses, ports, and other industrial operations, which allows for greater productivity, faster product movement, and other advancements.

Advancements Toward More Sophisticated Tasks

As automation becomes more common, the demand for AGVs increases. This leads to greater interest and investment in AGV technology. We’ve already seen how advancements in lidar technology have improved accuracy, navigation, and safety for AGVs.

Moving forward, innovations in AI have the potential to improve AGVs even more. Machine learning technology can enable AGVs to perform more sophisticated and intricate tasks, expanding their usage and delivering even more versatile solutions to businesses.

Smoother Technology Integration

One of the greatest benefits of automation is the ability to integrate technologies into a singular, easy-to-manage network. As AGV technology evolves, so does the ability to combine it with other applications in your facility. More sophisticated communication channels allow you to better coordinate technology applications and create a smoother, more connected operation.

This, in turn, leads to streamlined processes, greater visibility across your operation, and simplified workflow management. From improved workflow monitoring to more accurate analytics and data gathering, these advantages help you make informed, valuable decisions for your business.

The future of AGV technology is intertwined with the future of lidar systems. At Hesai Technology, we’re proud to be involved with both. As a leading supplier of digital lidar sensors for industrial automation, we help businesses enhance their operations with AGV solutions. When you visit us today, learn more about our role in lidar technology for industrial applications.