Lidar: The Missing Technology Needed to Advance the Automatic Assisted Breaking Vision

Safety will always be a critical consideration for consumers when selecting a vehicle. To meet this demand, active safety features in cars are continually evolving.

In particular, Automatic Emergency Braking (AEB) has garnered significant attention. AEB systems can detect road hazards in real-time, enabling a vehicle to automatically brake or decelerate, thereby preventing or mitigating accidents.

Compared to passive safety, active safety features are more effective in reducing traffic accidents. According to the European Commission, AEB can save over 1,000 lives annually in the EU alone, and 80% of consumers want vehicles equipped with AEB.

Given this preference and the life-saving benefits, on April 29 the U.S. Department of Transportation (U.S. DOT) issued a new regulation regarding AEB. FMVSS No. 127 requires AEB to be a standard in all U.S. cars by 2029. Furthermore, AEB systems must have effectiveness in identifying pedestrians in both daylight and darkness and functionality at speeds up to 90 mph (145 km/h).

Although many in the industry welcome these new standards, the reality is that most auto technology in passenger vehicles today cannot support these requirements. The solution: lidar.

Lidar works in all lighting conditions

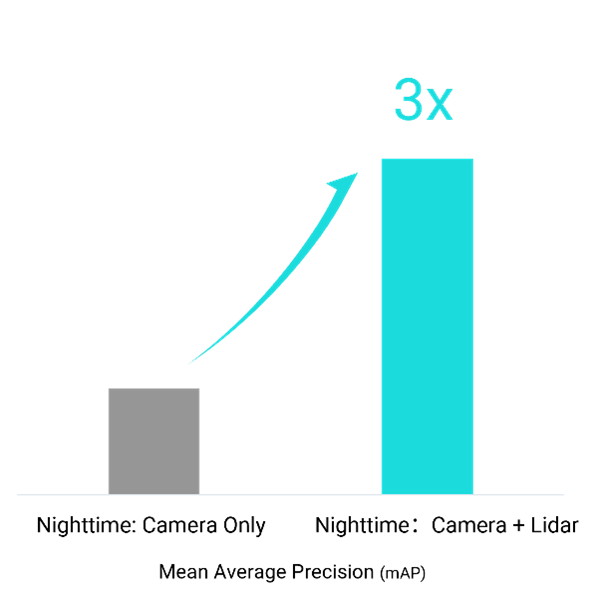

Lidar, which achieves direct detection by actively emitting lasers and does not rely on ambient light, can greatly enhance nighttime AEB safety when its data is used for AEB function development. Data proves that at night, the average perception accuracy of systems integrating lidar data is three times that of purely visual systems.

Lidar can identify and classify varying obstacles

The recognition ability of cameras for irregular obstacles is limited. Purely visual sensors require prior classification of target objects and cannot effectively identify atypical objects outside of a predetermined whitelist. For example, a vehicle carrying a large tree or a two-wheeled electric bike loaded with goods may have typical features obscured, making it difficult for visual algorithms to classify and identify them.

Purely visual AEB systems may encounter difficulties in recognizing irregular objects.

Similarly, lidar has the advantage of direct measurement. Regardless of the type of target object, as long as data can be sensed, it can determine the position of obstacles. AEB integrated with lidar is more capable of recognizing irregular obstacles and achieving safe braking.

Lidar provides greater perception at high speeds

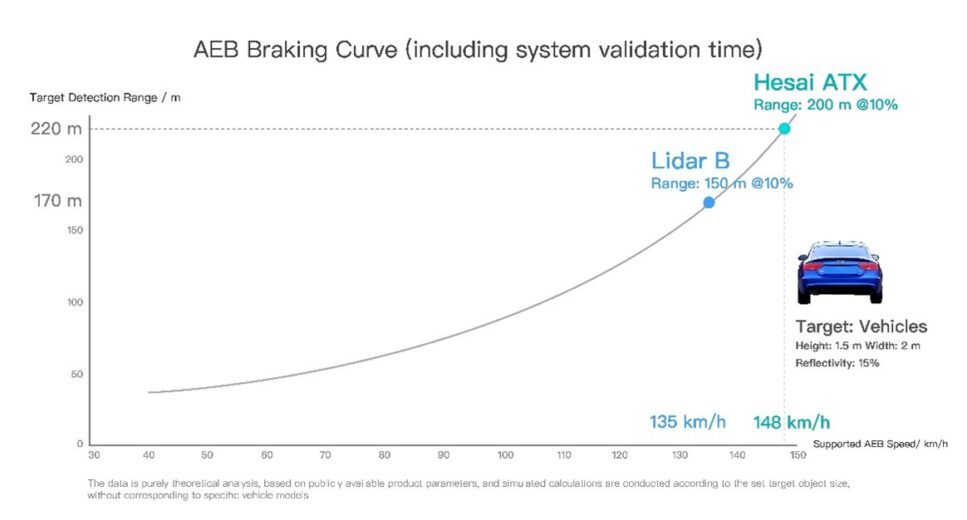

The current upper limit of AEB operating speed needs further improvement. For example, the new regulation from the U.S. DOT imposes higher requirements on the speed at which AEB must operate. Compared to previous regulations, the maximum operating speed of AEB for vehicles has nearly doubled, reaching 90 mph (145 km/h). This therefore requires vehicles to have higher perception distances and confidence levels.

An investigation into leading intelligent automobile brands revealed that models equipped with lidar show a significant increase of about 50% in the upper limit of AEB speed compared to models without lidar.

Lidar reduces false activation of AEB

The current high rate of false activations in AEB systems is affecting the overall riding experience. Insufficient ranging accuracy or complex lighting conditions can lead to misidentification of objects by purely visual systems, thereby triggering dangerous false activations of AEB. There have been numerous cases of consumer complaints regarding false activations, including instances such as false activations on steep slopes, from vehicle exhaust, or due to metallic plates on the ground. With lidar, the number of false positives of AEB is also reduced by almost 70%, creating a safer and more accurate braking system.

In scenarios like entering tunnels or environments with complex lighting conditions, purely visual AEB systems are prone to false activations. Source:https://zhuanlan.zhihu.com/p/163057084)

The Market Leader in Lidar

Hesai, a leading global lidar company, has always been committed to providing high performance, quality, and reliability in its lidar products for automobiles. Hesai closely monitors the end-use scenarios of lidar, particularly in critical safety components like AEB, which can prevent accidents and save lives. With automotive safety as its goal, the company continuously iterates its product features.

This year’s flagship release, the ATX, marks a significant upgrade with the transition to the fourth-generation technology platform. Not only has it seen significant improvements in metrics like ranging and resolution, but it has also introduced new features such as optical zoom and noise reduction. The ATX is set to enter mass production in Q1 2025, with models equipped with it meeting consumers soon after. With its abundant safety capabilities, the ATX aims to safeguard every passenger.

As car manufacturers globally look to comply with consumer preferences and regulations around AEB, Hesai products can serve as the missing piece of the puzzle, creating a safer driving experience and reducing accidents.