How Do Utopilot L4 Autonomous Trucks “See the Roads” in the “Driverless Test”?

Shanghai Yangshan Deep Water Port is the world’s largest container terminal. With a throughput of 22.813 million TEUs in 2021, Yangshan Deep Water Port has been rated as the world’s largest container port for the past 12 years.

As the only connection between Yangshan Deep Water Port and Shanghai, the 32.5km-long Donghai Bridge is suffering from huge traffic pressure. For a long time, influenced by factors such as busy transportation schedules of the ships, truck drivers usually have to wait for 2-3 hours every day, which leads to traffic chaos, low efficiency and other problems, causing serious traffic congestion on the bridge.

The Donghai Bridge is the only land transportation channel of Yangshan Deep Water Port

In 2019, Utopilot, Shanghai International Port Group, and China Mobile Group Shanghai have implemented the “Yangshan Port Autonomous Trucking Operation Project,” which became one of the first commercial applications of autonomous driving in China.

Utopilot L4 autonomous trucks

On July 18, Utopilot has officially initiated the L4 autonomous trucks’ “driverless test” on Donghai Bridge. At present, it has successfully passed the first stage of the stress test with safety operators sitting in the vehicles, and achieved zero takeovers in 1,500 kilometers.

Next step, Utopilot will start testing its autonomous trucks platooning, with the first and last vehicles having safety operators, and the three vehicles in the middle without safety operators. The ultimate goal of Utopilot is full self-driving.

Aiming for commercial application and planning IPO in three years

Early in 2013, SAIC has started autonomous driving research. In 2019, it started the test of autonomous heavy-duty trucks, accumulating a massive amount of data.

Currently, the self-driving mileage of Utopilot has exceeded 3 million kilometers. In addition, relying on the collected data and operational experience, with SAIC’s technical strength and partners ecosystem, Utopilot’s platooning is among the top in the industry. With the large-scale application of autonomous vehicles, it is expected that the traffic capacity of the Donghai Bridge will be further increased by 1.5 times.

Wang Rui, CEO of Utopilot, believes that “the value of autonomous driving companies is cost reduction and efficiency improvement. For the commercial vehicle market, intelligence is inevitable. For example, for a single self-driving truck that runs day and night, we can save 24 hours of human resources every day, which means we will save 500,000 – 600,000 RMB in one year.”

This year, Utopilot’s autonomous trucks will handle 100,000 TEUs on Donghai Bridge. The company is hoping to reach 1 million TEUs’ target in the future.

Utopilot L4 autonomous truck on Donghai Bridge

Utopilot’s self-developed unmanned all-electric smart flat vehicles (AIV) have been deployed at Waigaoqiao Phase 4 Terminal and Ningbo Container Terminal. It is planned to complete the transshipment target of 100,000 TEUs at the Waisi Wharf. In Ningbo Daxie China Merchants International Container Terminal, Utopilot also plans to realize unmanned operation in the empty container areas of the mixed traffic scenes.

In Caofeidian Port, Utopilot’s electric heavy-duty trucks will provide 60 million tons of transport capacity for four consecutive years; in Erenhot, 1 million tons of ore will be transported every year; in Lingang, its unmanned sanitation vehicles and unmanned buses have also begun to operate in small scale.

Utopilot unmanned sweeper

“Next year, we hope to expand multiple scenes and realize commercial application; by 2024, our goal is to achieve scaling operations; by 2025, when our mainstream businesses reach industry-leading level, we will go for IPO,” said Wang Rui, CEO of Utopilot.

The full-stack intelligent driving system makes “driverless” possible

Unlike other autonomous driving companies, all Utopilot products are equipped with their self-developed Honghu intelligent driving system, which is more generalized, efficient, and intelligent.

This system applies to the entire product line. The GPU computing power reaches 500+TOPS, which supports complex deep learning algorithms. It also has excellent CPU computing power to realize complex logical operations and communications.

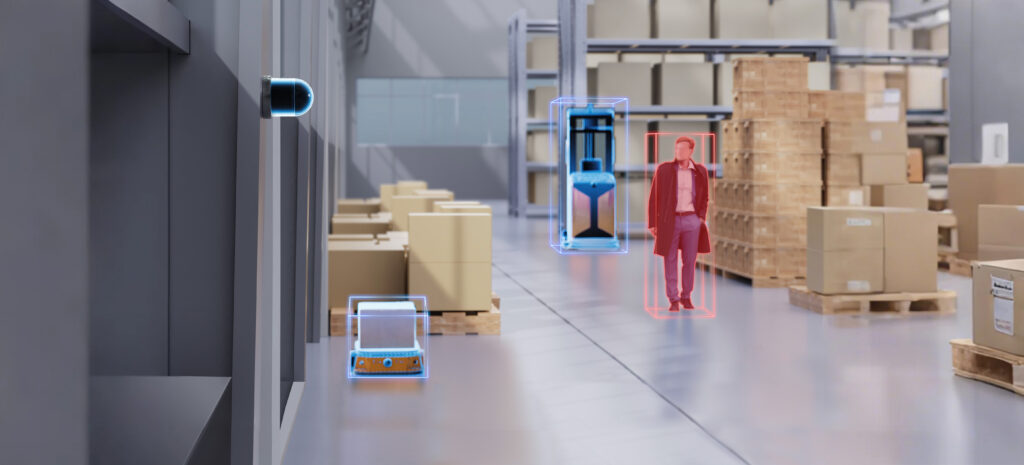

In addition, the Honghu intelligent driving system has perception algorithms of high precision and strong generalization capability. The integration of laser, millimeter wave, vision, and multi-sensors achieves long-distance, high-precision, and high-robust perception, creating a long-distance perception system within a 3*360° 1000-meter distance.

The self-developed centimeter-level, high-fidelity and high-precision map of the Honghu platform provides all-weather and full-scene location information to meet precise positioning in different scenes.

Image-like perception helps L4 autonomous trucks to achieve “unmanned” driving

Utopilot L4 autonomous truck carries Hesai’s high-performance lidar – Pandar series.

Utopilot L4 autonomous truck carries Hesai’s Pandar128

01 Excellent detection capability plus image-like resolution

Pandar128 has image-like resolution both horizontally and vertically. Its vertical angular resolution is 0.125° (-6° to +2°); its finest horizontal resolution can reach 0.1° at 10Hz rotation speed, which is the best of its kind.

High resolution and 3D environment image-like reproduction of Pandar128

The Donghai Bridge has complex road conditions, especially during the night. Pandar’s image-like point cloud helps the Utopilot L4 autonomous truck to “see the road” clearly. Even when the light is poor at night, it can fully obtain the road information and ensure safe driving.

Pandar128 is able to detect 10% reflectivity targets over 200 meters away under 100 klux ambient illuminance, while keeping false positive rate below 1E-5. The lidar helps the vehicle to sense and identify the road conditions, providing a longer reaction time so the truck can avoid obstacles, change lanes, and detour in time.

02 Reliability creates strong environmental adaptability

Pandar128 has automotive-grade core components (meeting AEC-Q and other relevant standards). The DV test covers over 50 automotive-grade tests such as electrical, mechanical, climate, sealing, material, and electromagnetic compatibility by international OEM standards. Pandar has strong adaptability, enabling the truck to operate stably in all weather conditions.

Pandar128 passed rigorous automotive-grade tests

03 The world’s first lidar to receive ISO 26262 certification

Pandar128 received ISO 26262 (functional safety standard) ASIL B certification issued by SGS-TÜV in 2021, becoming the first lidar in the world to obtain this certification. Even in the event of failure, the lidar will timely transmit “fault information” to the vehicle within 100ms, effectively improving safety.

“In ports, we have high requirements for lidar’s accuracy, sometimes within ±3cm. It is necessary to meet the detection capability of 10% reflectivity within 200 meters and ensure stable performance in different weather conditions. After comparing various indicators, we chose Hesai,” Wang Rui, CEO of Utopilot, said, “In the future, I hope we can have deeper cooperation in more application scenarios.”