If you’re looking to use automated guided vehicles (AGVs) in your warehouse, one of the first things that you should consider is which type of lidar system is best for navigating your facility. In an age of constant technological advancement, 3D lidar is rapidly replacing its 2D predecessor as the preferred sensing system for autonomous vehicles. This article will discuss the advantages of 3D vs. 2D lidar in AGV applications and provide an overview of how they can benefit your industrial facility.

How Lidar Technology Serves AGVs

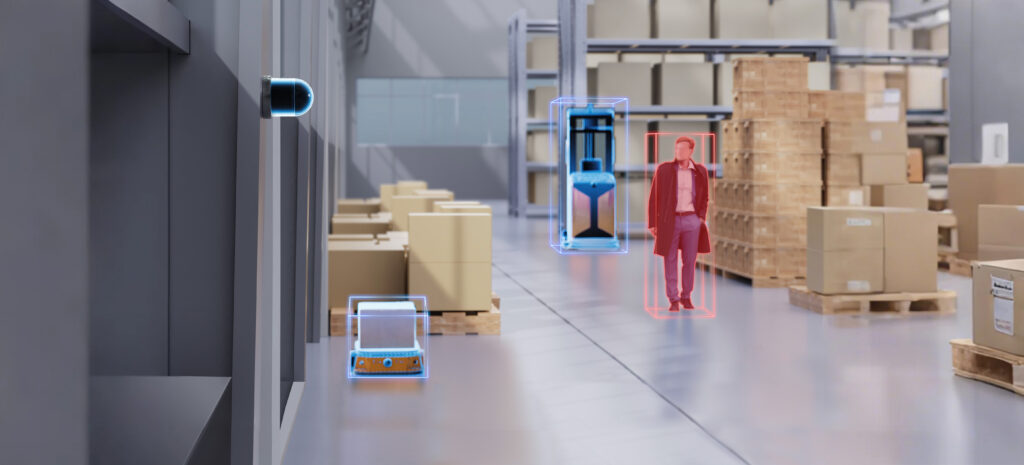

Lidar has become increasingly popular in AGVs due to its accurate perception capabilities and its ability to detect objects, even while in motion. Lidar systems allow AGVs to gain an accurate vision of the surrounding environment and safely navigate the area. Additionally, lidar applications improve obstacle avoidance. As the AGV scans its surroundings, it can detect obstacles, including walls or other objects, and instruct the vehicle to adjust its route accordingly. With this capability, AGVs can travel through complex environments with unprecedented accuracy.

3D Lidar Creates Greater Accuracy

The key difference between 2D and 3D lidar systems comes down to accuracy. While 2D lidar systems can measure distance by bouncing light off a single surface, 3D lidar systems expand on that by using multiple beams of light simultaneously to create a three-dimensional view of the area. As a result, 3D lidar technology can accurately capture the subtlest of nuances in shape and form. Moreover, because 3D lidar sensors create more in-depth point clouds to perceive their surroundings, they have an easier time detecting low-reflectivity objects or sensing obstacles in adverse conditions.

Benefits of 3D Lidar for AGVs

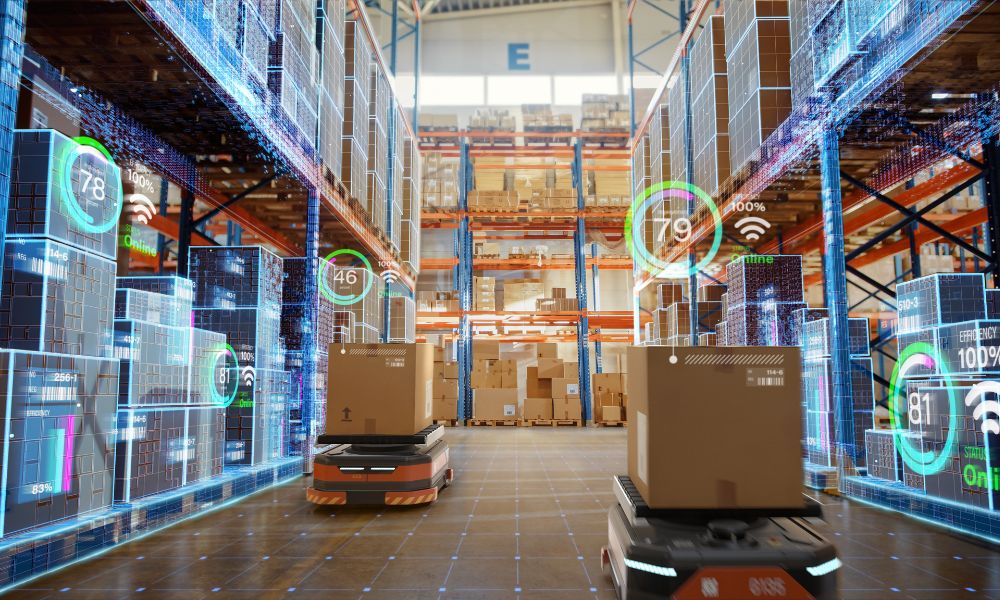

Because of its incredible accuracy and thorough perception, 3D lidar offers unprecedented possibilities for AGV applications. Using such highly precise navigation data ensures reliable collision avoidance resulting in less time spent rerouting, manually redirecting, or sorting out traffic jams on the warehouse floor.

Additionally, 3D runs much more smoothly than traditional optical sensors, making it the ideal solution for navigating warehouse aisles while avoiding potential collisions with other vehicles or any physical barriers that exist.

With superior accuracy, safety, and dependability, the advantages of 3D lidar over 2D lidar in AGV applications are clear. At Hesai Technology, our team uses cutting-edge 3D lidar systems to power durable and versatile AGVs and other industrial lidar applications. Learn more about our lidar sensors when you visit our website today.